Last week we held our third sustainable forum, and we are thankful and proud of all who helped make it a success. Each event has seen to a growth in our audience, and we love being able to spread the word regarding high-performance homes. Below is a brief synopsis of some of the conversation had during the panel. We hope you find it informative and make sure to keep an eye out for our next event which will focus on financing.

Are there ever issues with the town codes when building these homes?

Unfortunately, there can be. Since panelized and factory-built homes can have design features built into the walls, sometimes older codes are unable to be verified in traditional means. However, this doesn’t have to be an issue. Not only can you go to the town prior to building to explain the unique and advance features of a high-performance home, but the companies producing these buildings also have a safety net. Many companies work with third-party inspectors throughout the process to ensure home-owners don’t have issues.

What about issues with appraisers?

Again, this is something that can be an issue, but as a home-buyer/builder you have rights to protect your investment. An issue that has arisen is that many times there are no comparable homes to refer to. Usually when someone builds a ‘green’ home, they stay in them for life so it’s hard to determine the value of a build from years prior. Also, appraisers won’t calculate energy savings into the mortgage, despite how much of a cost-saving benefit this is. But you have the right to require a green-certified appraiser for your home. Carlyn with BrightBuilt gave the example of one of her homes being first appraised at $375,000, and then after requesting a green-certified appraiser it was appraised at $580,000. This is a perfect example of the control you have and the difference it can make!

What are the constraints on this market that have slowed its progress?

Surprisingly many building practices haven’t advanced since the middle ages. Most people wouldn’t go out and buy individual materials and pieces for a car and bring them back to a site to be assembled by skilled laborers, and yet that is how most homes are still built. This plays into a catch 22 of demand and knowledge. Since these homes are built in a superior fashion, they need crew who are familiar with their makeup to be assembled. It’s hard and time consuming to send factory workers to a site to assemble a home. Yet because these houses aren’t being built as frequently as traditional homes, there isn’t enough outside labor that has learned the process. It’s also a massive investment to create a facility where engineered homes are built, which limits the industry growth. All these factors play a role in limiting the industry.

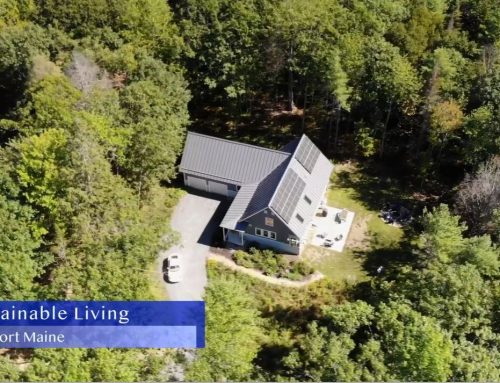

A special thanks to Unity Homes, GO Logic, BrightBuilt Homes, and the Shelter Institute for providing a wealth of knowledge to us all. If you’re interested in a precision-engineered home in Brunswick, reach out to us via email at info@mainehomeconnection.com.

Moving to Maine?